The safety fuel vapor generator (nitrogen bubble method) is an important accessory equipment belonging to the carbon canister measurement test system. Its function is to realistically reproduce the true working state of the car. Generate sufficient fuel vapor to load the charcoal canister. Measure the actual working capacity of the carbon canister. The previous method of generating steam through fuel heating was neither safe nor accurate. Often unable to obtain the expected experimental results. And our safety fuel steam generator (nitrogen bubble method) is an advanced method that has been adopted first in developed countries in the European and American automotive industries. There are significant advantages in terms of safety and accuracy of fuel vapor measurement.

Adopting experimental standards

- Chinese National Emission Standard GB 18352.5-2013

- Chinese National Emission Standard GB 18352.6-2016

- Chinese National Motorcycle Evaporative Emission Standard GB 20998-2007

- Chinese National Environmental Protection Industry Standard HJ/T 390-2007

- US Emission Standard EPA Regulation 86.132-96

- American GM Enterprise Standard ORVR

- European Emission Standard V Stage, VI stage

- Ford Carbon Can Standard ES-8U5A-9E857-AC

- Volkswagen Standard TL 820 19

- Mazda Standard MES PB 1397 for US

working principle

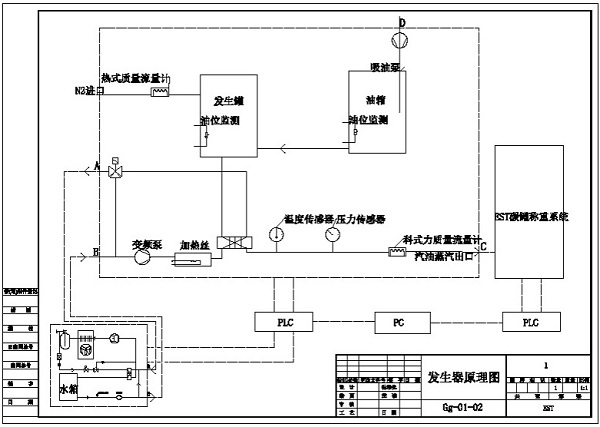

The working principle of a steam generator is to introduce nitrogen gas into a device containing gasoline, mix the nitrogen gas and gasoline solution thoroughly in the steam generation device through vortex, and then output gasoline vapor to the outside. The equipment adjusts the output flow of gasoline vapor by adjusting the nitrogen intake flow rate and the liquid level height of the gasoline storage device; And the temperature control unit of the equipment is used to regulate the temperature of the gasoline vapor output to achieve gasoline vapor output that meets the standard requirements. This device achieves the requirements of controlling and recording the temperature and output gasoline steam flow of the steam generator through EST's self-developed PLC and touch screen.

The main structural components of the product include an alloy aluminum frame structure, an oil storage unit, a fuel pump, a fuel vapor generator unit, a flow metering unit, a gasoline concentration detector, a temperature control unit, an electromagnetic valve switch, a temperature and liquid level switch, a Siemens PLC, an electric control box, and other components. The gasoline vapor flowing through the pipeline is insulated to effectively solve the problem of condensation of gasoline vapor in the pipeline.

Design specifications

Alloy aluminum frame dimensions: 500mm (length) * 500mm (width) * 800mm (height)

Steam generator generation unit:

The maximum volume is around 20L; Actual effective working volume is about 12L

Oil storage tank unit:

400mm (length) * 400mm (width) * 100mm (height)